A40 aluminum alloy U-channel all-glass guardrail tsarin tsarin tsarin gine-ginen zamani ne wanda ya haɗu da kayan ƙarfi mai ƙarfi tare da ƙirar ƙira, kuma ainihin abubuwan sa sun haɗa da masu zuwa.

1. Tsarin tsari da kaddarorin kayan aiki.

A40 aluminum gami U-channel

An yi shi da manyan bayanan allo na aluminum mai ƙarfi (A40 yana tsaye ga Aluminum Model), waɗanda suke da nauyi, juriya da iskar shaka da iskar shaka, ƙirar U-channel tana ba da tallafi mai ƙarfi ta hanyar nannade gefen gilashin yayin sauƙaƙe tsarin shigarwa. Firam ɗin yawanci ana daidaita shi zuwa tsarin ginin ta hanyar faɗaɗa ƙusoshi ko ƙusoshi masu harbi, tare da ƙasa da maki 3 na gyara kowane gefe don tabbatar da kwanciyar hankali.

10+10 Laminated Glass Tempered

An yi shi da yadudduka biyu na gilashin kauri na 10mm mai kauri wanda aka haɗa ta fim ɗin PVB, yana haɗa ƙarfi da aminci. Ƙarfin tasirinsa shine sau 4-5 mafi girma fiye da na gilashin yau da kullun, kuma har yanzu ɓangarorin suna manne da laminate Layer bayan karya don guje wa splashing da raunin da ya faru. Za'a iya daidaita kauri na gilashi bisa ga buƙatun, kuma girman girman (misali karuwa a tsayi ko faɗi) na iya inganta ƙarfin iska gabaɗaya da ƙarfin ɗaukar nauyi, wanda ya dace da yanayin ɗaiɗaikun ɗaiɗaikun ko manyan-span.

2. Kaddarorin jiki da ƙarfin kaya.

Babban ƙarfi da ƙarfin kaya

Tsarin laminated sau biyu yana inganta haɓakar danniya da juriya na iska na gilashin. Misali, 10+10 laminated gilashin yana da ƙarancin canja wurin zafi na 2.39 W/m²-K (shigarwa mai layi biyu) da kuma sautin sauti na har zuwa 38 dB, yayin da a lokaci guda yana iya jure wa mafi girman nauyin iska (ta hanyar ƙididdige tsayin da aka dace ta hanyar modul lanƙwasa).

Babban Girman Amfani

Lokacin da tsayi da nisa na gilashin ya karu, ana buƙatar ƙididdige ƙididdiga na injiniya tare da tazarar tallafi na tashoshi U da yawa na wuraren gyarawa na firam. Alal misali, ana buƙatar ƙarin ƙarfafawa lokacin da tsawon gilashin U-dimbin yawa da aka sanya a cikin jere guda ya wuce 4m, kuma shigarwar layi biyu na iya ƙara inganta zaman lafiyar gaba ɗaya.

3. Tsarin shigarwa da cikakkun bayanai.

U-channel ƙayyadaddun shigarwa

Ya kamata tazara na tsagi ya kasance daidai (yawanci ana sanya shi ta tef ɗin taimako), kuma ana buƙatar zurfin shigar da gilashin: firam na sama ≥20mm, ƙananan firam ≥12mm, firam ɗin gefen hagu da dama ≥20mm. Bayan cika rata tare da tsiri na roba (lamba mai lamba ≥10mm), ana ɗaukar hatimin silicone don jure haɓakar thermal da ƙanƙantar sanyi.

Matakan Kariya

Ƙarshen gilashin yana buƙatar padded tare da gaskets anti-lalata, kuma saman an ajiye shi tare da ≥25mm fadada haɗin gwiwa tare da tsarin ginin. Firam ɗin alloy na aluminum da sassan gyaran ƙarfe ya kamata a sanye su da kayan gaskets na roba don hana lalata galvanic.

4. Yanayin Aikace-aikacen da Sharuɗɗan ƙira.

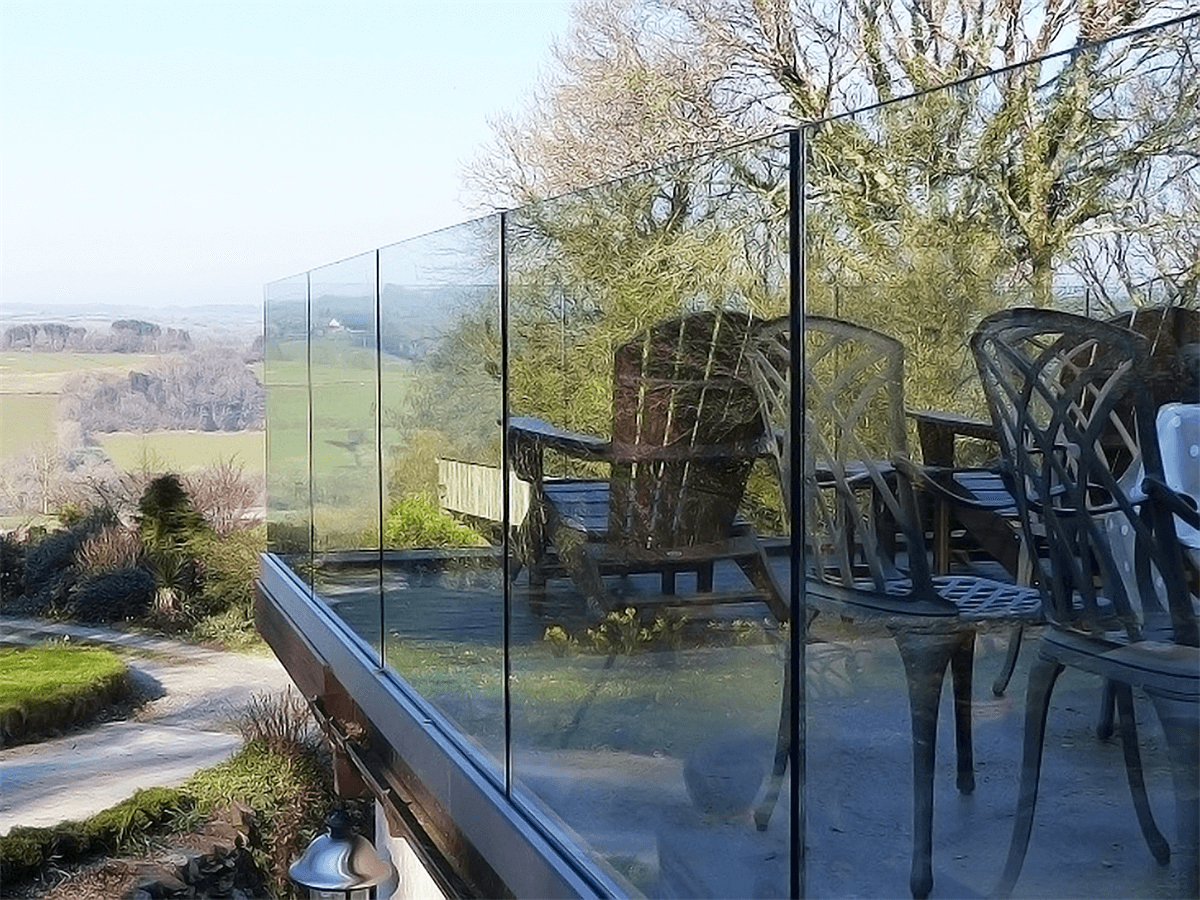

Yanayin aikace-aikace

Ana amfani da shi sosai a cikin baranda na zama, wuraren kasuwanci, filayen jirgin sama, jigilar jirgin ƙasa da sauran wuraren da ke buƙatar haɓaka da aminci. Adadin isar da haske zai iya kaiwa 81% (shigar da layi biyu), duka haske da kariya ta sirri110.

Ƙayyadaddun Bukatun

Tsawon tsayin daka ya kamata ya bi ka'idodin ƙasa (misali ≥1100mm daga ƙasa), rata tsakanin gilashin da tsagi ≤100mm, ana ba da shawarar kauri na gilashin ya zama ≥12mm, kuma nau'in da aka fi so yana tauri ko laminated don tabbatar da kadarar tsufa.

5. Tattalin Arziki da kulawa.

Cikakken Fa'idodin Kuɗi

Idan aka kwatanta da kayan aikin ƙarfe na gargajiya, tsarin tashar U-tashar zai iya rage girman ginin da 30% -50% kuma adana bayanan ƙarfe ta 20% -40%, kuma farashin kulawa yana da ƙasa, kawai buƙatar duba yanayin tsufa na sealant akai-akai.

Magana.

An yi amfani da irin wannan ƙira ga ayyuka irin su Pavilion na Chile a bikin baje kolin duniya na Shanghai da gidan kayan tarihi na Ningbo, waɗanda suka tabbatar da amincinsa da darajar sa.

Ta hanyar haɓaka kayan aiki da haɓaka tsarin, A40 aluminum alloy U-channel duk-gilashin guardrail yana gane haɗuwa da ƙarfi mai ƙarfi, babban aminci da kayan ado na zamani, wanda ya dace da yanayin girma da girma. Zane yana buƙatar bin ƙayyadaddun shigarwa da ƙididdiga na inji don tabbatar da kwanciyar hankali na dogon lokaci da yarda.

Lokacin aikawa: Mayu-21-2025